Main Menu

Main Menu

- Activities -

Overview of the BIOTECHWORKS-H2® Project Activities

History | Project Activities | Service Overview | CO2 Emission Calculator

Our Circular

Economy

What Can BIOTECHWORKS-H2® Do?

An Innovative Project Transforming Waste into Hydrogen Energy BIOTECHWORKS-H2®

BIOTECHWORKS-H2® is an innovative project with a mission to transform the majority of waste into renewable energy, driving a circular economy. This groundbreaking project started in July, after three years of planning.

Yamagin Inc., a company dedicated to developing and selling sustainable fabric materials, successfully developed a unique technology to convert discarded clothing into hydrogen through a chemical recycling process, without requiring sorting. To further advance circular economy initiatives, a related company was established as “BIOTECHWORKS-H2 Inc.” in Tokyo, Japan.

BIOTECHWORKS-H2® extends its scope beyond traditional clothing, aiming to transform all organic waste into clean hydrogen energy through a chemical recycling system. By doing so, the project connects businesses and individuals, resolves environmental challenges, and builds a circular economy without grey areas.

In the United States, BIOTECHWORKS-H2 Inc. entered into a partnership with a plant company to utilize their facility as a base. By adopting a gasification technique that avoids waste incineration, over 99% of organic waste can be converted into renewable energy. BIOTECHWORKS-H2® has already successfully demonstrated the conversion of 6-7% of waste textiles and 7-8% of food residues into hydrogen, setting it apart from similar projects.

This approach is cost-effective, as it doesn’t require fine grinding or incineration and is suitable for relatively small-scale plants. The gas generated in the gasification furnace is separated into hydrogen and CO2 (carbon dioxide). The hydrogen is recommended for use in fuel cells or hydrogen cogeneration, while the CO2, instead of being released, can be supplied to companies that require large amounts of CO2 for purposes such as carbonated beverages, dry ice, or welding.

One significant advantage is the ability to measure and visualize the collected and hydrogenated energy, CO2 reduction, and environmental contributions. Participating companies can effectively manage the waste collection, conversion, and hydrogenation processes. This enables retailers to assess CO2 reduction and environmental contributions before products even hit the shelves, using these metrics as ESG (Environmental, Social, and Governance) indicators.

A traceability platform and app developed by our specialized team enable the visualization of recycling and hydrogenation processes for endorsing companies. This system can be applied to various types of waste, including food residues from restaurants planning hydrogenation, office waste, and more. Proposals have already been made to shopping mall developers and local governments, aiming to create a future where “all waste becomes a resource, and waste is reduced to zero” by 2030.

BIOTECHWORKS-H2® is an unprecedented project that embraces environmental concerns and supports stakeholder development.

Our Circular

Economy

BIOTECHWORKS-H2® Circular Economy

Simply place your items in the designated collection box.

No further action required.

Trust us with the rest.

Participate in sustainable practices without altering your current lifestyle.

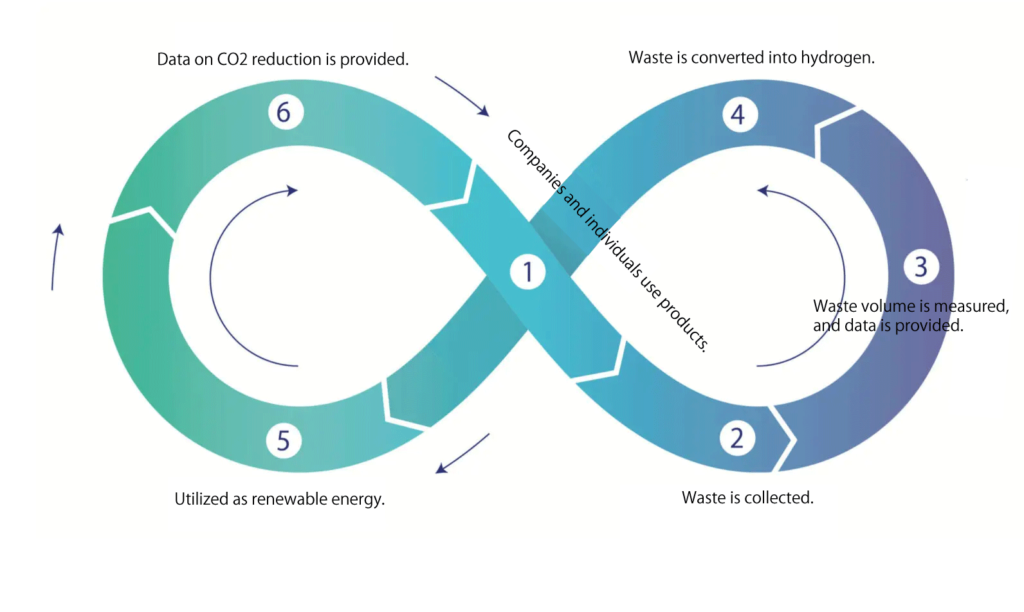

1.

Corporations and individuals continue to use products as part of their regular routines, making environmentally responsible choices when feasible.

2.

Waste materials are collected and transported to nearby BiotechWorks collection points.

3.

The volume of waste is meticulously measured and aggregated on a per-company basis. Recyclable items are processed accordingly, while others are directed to the plant.

4.

Upon reaching the plant, waste materials undergo gasification, a process that transforms them into hydrogen without resorting to incineration. This marks the successful production of hydrogen.

5.

The generated hydrogen is harnessed as a source of renewable energy, predominantly employed for electricity, vehicles, and public transportation.

6.

Quantifiable data regarding the extent of CO2 reduction is made available to collaborating companies. Rest assured, this process is a far cry from uncertain waste disposal, and it represents a genuine commitment to sustainability.

Your participation will save the Earth.

We are seeking like-minded companies to join us.

Through our cutting-edge technology, we can transform organic materials, the source of life, into renewable energy, hydrogen, without disposing of them. This project allows us to establish a circular economy, maintaining the inherent nature of organic materials in a sustainable and effortless manner.

The conventional approach to waste management, primarily focused on physical processes like incineration, has proven ineffective in reducing CO2 emissions over the years and has kept us trapped in the mindset that “waste equals trash.”

We are here to fundamentally change that perception.

© BIOTECHWORKS-H2®